In today’s volatile market, manufacturing leaders face relentless pressure. Managing supply chain disruption, minimizing machine downtime, and driving efficiency are no longer just goals; they are survival imperatives.

To compete, modern operations require agility and data-driven precision, yet many factories are hindered by a fundamental gap: a lack of real-time visibility and control over their shop floor processes.

Elansol’s WorkXpert is an AI-powered digital work instruction platform designed to close that gap. It moves beyond simple instructions to become a complete system for real-time production monitoring, AI-powered quality control, and end-to-end manufacturing process optimization.

This comprehensive guide explores what digital work instructions are, their key benefits for manufacturing efficiency, how they solve common production issues

Why Current Factories Methods Fail at Real-Time Production Monitoring

The core challenge of traditional manufacturing process management is a severe lack of real-time data and visibility. This data lag makes it nearly impossible to effectively manage operations, respond to disruptions, or implement lean manufacturing tools.

Research from Aberdeen Group shows that companies using paper instructions experience 40% longer training times and 60% more quality control issues compared to digital alternatives.

This outdated approach leads to several critical pain points:

Inaccurate Manufacturing Data Collection

- Manual data entry is prone to human error

- Production forecasts become unreliable and improvement efforts are misdirected

- Decisions based on flawed data lead to incorrect inventory levels

- Version control becomes impossible across multiple production lines

Delayed Response to Quality Issues

- Quality defects are often discovered only during final inspections

- Hundreds of faulty units may be produced before an issue is identified

- Lack of instant feedback results in significant scrap and rework

- 67% of quality issues stem from operator confusion or outdated procedures

Difficulty Optimizing Workflows

- No live data means decisions rely on historical averages and guesswork

- Managers can’t detect small stops, slowdowns, or bottlenecks in real time

- Different shifts interpret procedures differently

- Dynamic work order management is impossible without real-time visibility

Manual and Inefficient Error Analysis

- Investigations require digging through stacks of paper

- Rework rates increase by 45% when operators use unclear instructions

- Material waste rises 23% due to procedural mistakes

- Time-consuming and often inconclusive root cause analysis

- Error reduction efforts are hindered by lack of timely, accurate insights

What Are Digital Work Instructions? Smart Manufacturing Solution

Digital work instructions are the foundation of smart manufacturing. They are interactive, media-rich, and data-driven guides that present operators with the exact information they need at the exact right time. These electronic work instructions transform static procedures into dynamic, engaging experiences.

Crucially, they serve as the primary interface for your manufacturing data collection system. Every action an operator takes is captured as a valuable data point. As an AI-powered platform, WorkXpert streamlines operations, reduces defects, and boosts efficiency, becoming the central hub for:

- Standardizing Operations: It ensures every operator follows the exact same approved procedure. This consistency is the core of any effective work order management system and the first step toward digital quality management.

- Collecting Data: The system automatically captures cycle times, quality results, and material consumption, providing a granular, accurate view of shop floor reality.

- Enabling Lean Manufacturing: The rich data gathered is the fuel for continuous improvement, providing the clear evidence needed to identify and eliminate waste.

- Automating Workflows: As a key component of production workflow software, WorkXpert can integrate with other systems to trigger actions based on operator input.

Benefits of Digital Work Instructions for Manufacturing Efficiency

Implementing a robust system for digital work instructions moves beyond simply replacing paper. It unlocks significant, measurable gains, with companies using WorkXpert seeing up to 90% reduction in manual errors and a 50% improvement in productivity efficiency.

1. Enhance Quality Control Software Capabilities with Digital Checks

WorkXpert’s AI Quality Control System acts as the frontline for your quality initiatives. Operators follow guided digital checks, capture images of defects, and input measurements directly at the source. This enables proactive manufacturing defect reduction by catching deviations the moment they occur. The result is a 40% improvement in quality and a dramatic reduction in costly rework.

2. Enable Real-Time Production Monitoring from the Shop Floor

WorkXpert provides a live dashboard view of every workstation in your facility. Because every step is tracked, managers can instantly see if a process is running, paused, or encountering an issue. This immediate visibility allows for rapid intervention to resolve problems, reallocate resources, and minimize disruptions.

3. Integrate with Preventive Maintenance Software by Tracking Machine Usage

Unexpected equipment failure is a primary cause of lost production. With WorkXpert, operators can use integrated forms to report machine abnormalities. This data can automatically create a work order in your preventive maintenance software. This proactive approach is essential for effective machine downtime tracking and shifts maintenance from a reactive to a predictive model.

4. Serve as a Core Lean Manufacturing Tool to Eliminate Waste

The principles of Lean Manufacturing depend on accurate data. WorkXpert provides this data with unparalleled precision by standardizing work and capturing exact cycle times. It helps identify bottlenecks, optimize workflows, and provides a clear baseline for improvement initiatives, making it one of the most effective lean manufacturing tools.

Digital Work Instruction Software for Smart Factories & Manufacturing Units

A platform for digital work instructions should not be an isolated data silo. WorkXpert is designed to be the connective tissue for your factory’s digital ecosystem, providing seamless integration with your existing systems.

This capability is critical because a Manufacturing Execution System (MES) is only as good as the data it receives. WorkXpert powers your MES by feeding it clean, accurate, and immediate data directly from the operators. This enriches your high-level systems with real-world context through:

- IoT Integration Services: Connects with shop floor sensors and devices to automate data collection and trigger process steps.

- ERP & MES Integration: Ensures operators are working from the correct bill-of-materials and that production progress is updated in real-time.

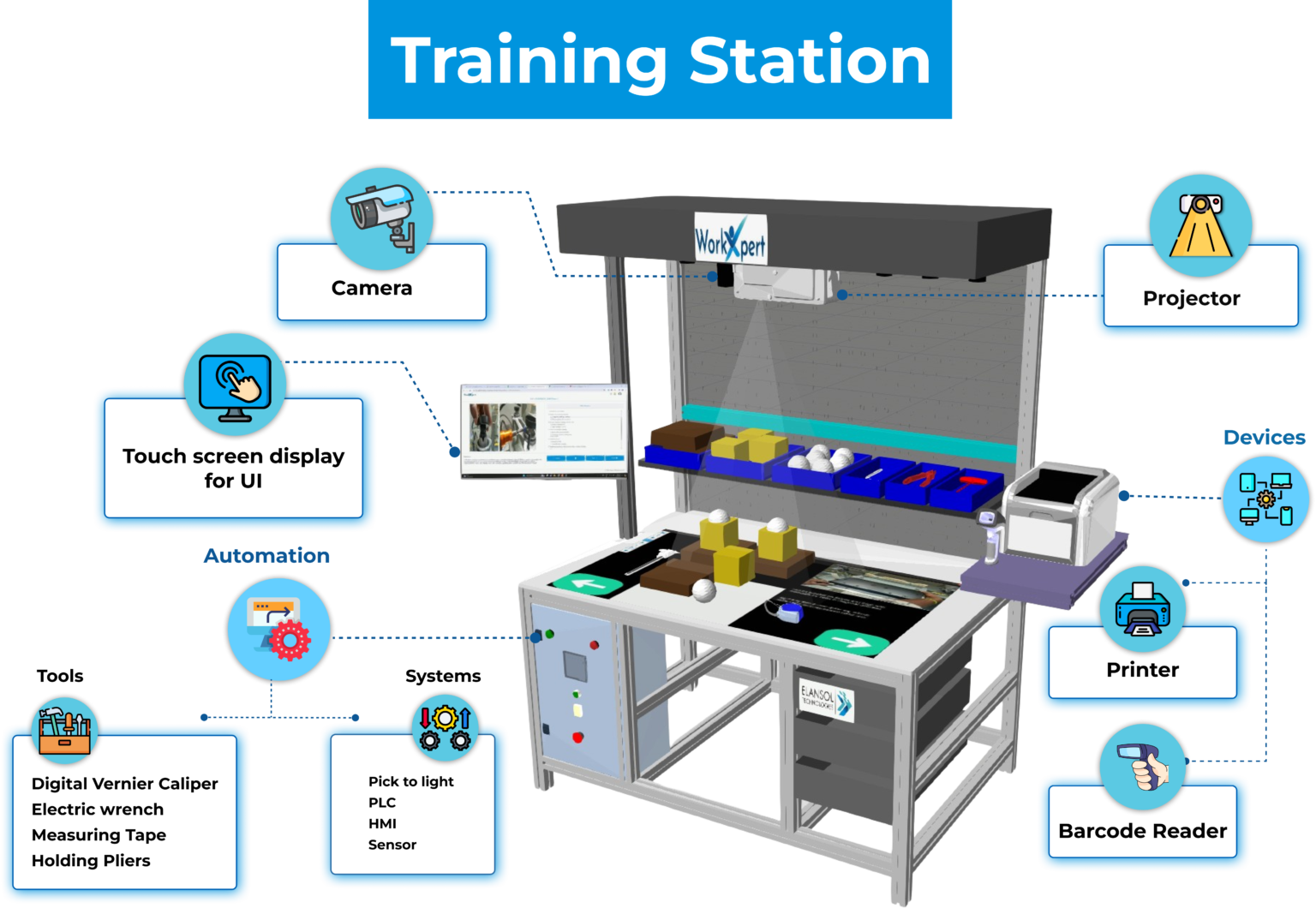

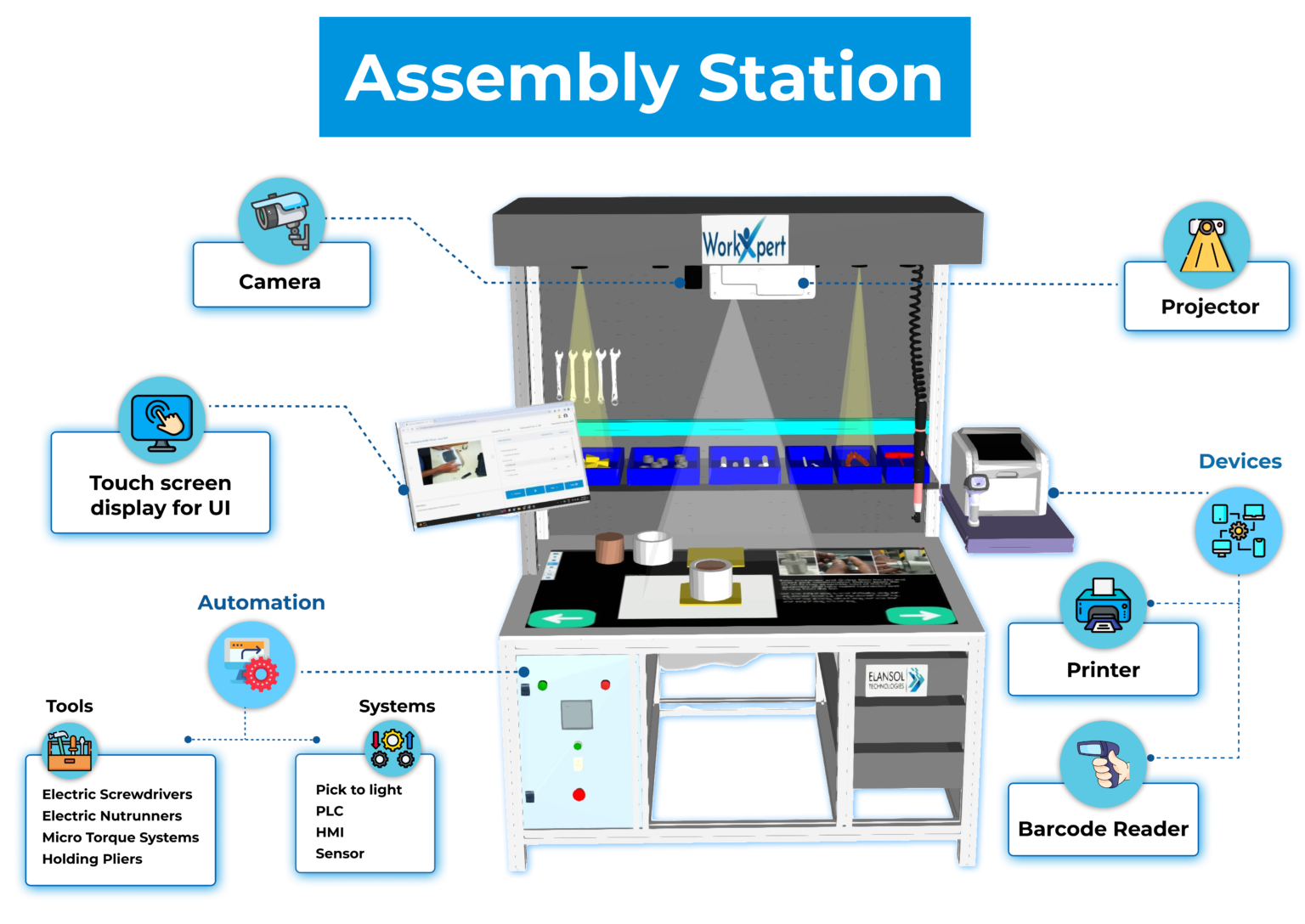

- Projection Integration: Uses Mixed Reality (MR) projections for enhanced, hands-free operator guidance in complex assembly tasks.

Real-World Proof: Success with a Leading Automobile Manufacturer

Theory is one thing, but results are what matter. For a leading automobile filtration production company in India, WorkXpert was implemented to solve critical challenges around manual SOP adherence and a lack of process traceability.

The results were transformative:

- Achieved 100% SOP Adherence: Digital instructions ensured every operator followed the correct procedure, every time.

- Eliminated Manual Errors: The AI vision system validated each step, moving the client towards zero-defect production.

- Enabled Real-Time Monitoring: Management gained complete visibility into the production line, allowing for proactive adjustments.

Ready for Smart Manufacturing? See Elansol's WorkXpert in Action

WorkXpert is the solution that embodies all the benefits discussed, providing a comprehensive platform for manufacturing process automation and optimization. Tired of operational guesswork? Discover how WorkXpert can transform your manufacturing processes.

Request a Demo to see WorkXpert’s capabilities firsthand and discuss your specific manufacturing challenges with our experts.

Explore WorkXpert to learn more about our intuitive digital work instruction software and its comprehensive feature set designed for modern manufacturing environments.

Conclusion: The Future of Manufacturing is Connected and Data-Driven

The manufacturing industry stands at a critical inflection point. Companies clinging to paper-based processes will fall behind competitors who embrace digital transformation and leverage data-driven improvements.

Digital work instructions represent more than technology upgrades. WorkXpert provides the foundation for this transformation, enabling companies to achieve operational excellence while preparing for Industry 4.0 requirements.

The future belongs to manufacturers who invest in their workforce through better tools, clearer guidance, and data-driven decision-making.